Vertical Liquid Silicone Rubber (LSR) Injection Molding Machine

liquid silicone injection molding machine Applications: Liquid silicone injection machines are often used in medical car

Basic Info

| Model NO. | 85T |

| Transport Package | Wood |

| Specification | ls-850 |

| Trademark | DAHUA |

| Origin | China |

| HS Code | 84778000 |

| Production Capacity | 1000sets/Year |

Product Description

liquid silicone injection molding machine

Applications:

Liquid silicone injection machines are often used in medical care, labor insurance, electronic packaging, adult products, baby products and other industries:

1)Liquid silicone daily used products: gloves, cup mat, ice cube tray, menstrual cup and so on.

2) Liquid silicone baby products: baby nipple, baby pacifier, baby soother, baby toothbrush, baby silicone bottle, silicone toys, etc.s

3)Liquid silicone diving & swimming products: swimming supplies, diving supplies

4) Liquid silicone medical part: prosthetic, the capsule, laryngeal mask capsule, oxygen mask, protective mast, catheter, balloon, medical belt etc.

5)Sex toys/adult products, which vibrating spear, sex toy coat, adult supplies etc.s

6)Electronics and industrial product: watchband, mobile phone case, valve, O-ring, sealing part, auto parts and more.

7)Silicone high-voltage cable accessories

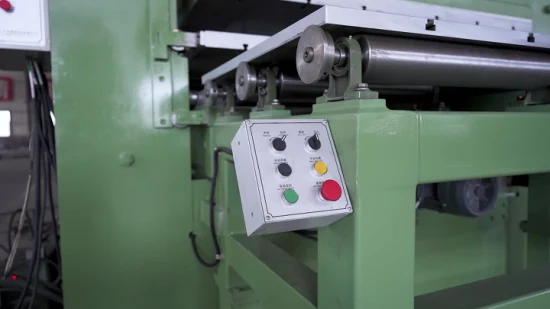

Features:

- Fasten lower mold, upper mold will be controlled by up/down switch. Enough space for insert parts and finishing goods releasing.

- High speed clamping molds by hydraulic oil, low speed increasing pressure, friendly adjust pressure and speed, no impact noise when open molds.

- Pilot-operated type adjusting pressure, stable and useful. Quick reaction & energy conservation.

- Two phases injection speed & pressure controlling, independent module conduct melting and injection to ensure quality.

- Import electronic components from Europe & Japan, computer control machine, digital speed & pressure & timing & cycle calculating will be appeared on LED.

1.Multiple phases precision mold electric heating temperature control;

2.LSR machine has special hydraulic oil pressure and cooling water sealing nozzle;

3.Specialized barrel for LSR machine.

4.Hot & cool water switch board and insulate glass fiber board;

5.Taking/placing parts with disc or single/double plate design, use LSR machine to control thermosetting molding and dwell time, operator can take/put insert port product from another molds, or clean molds, greatly increase efficiency.

6.Special feeding & injection design, precise measurement in feeding.

7.Separately order adjustable vacuum device to prevent bubble.

8.Various hydraulic oil system (Semi-Closed Loop, Servo motor or high-speed injection) designs can meet customer requirements.

please send the message about your requirments below to customized your product,KIndly share your mold & plastic products drawings with me will be highly appreciated.let's get the effective communication.1)raw material of your product2)net weight of product as well as the runner weight3)mold dimension if you have in hand

Specification

Item | Unit | DHLS-850 | DHLS-1200 | DHLX-1500 | ||||||||

Injection device | Screw Dia. | mm | ¢26 | ¢28 | ¢30 | ¢30 | ¢35 | ¢40 | ¢40 | ¢45 | ¢50 | |

Ideal Injection volume | cm3 | 74 | 86 | 98 | 98 | 134 | 175 | 251 | 317 | 392 | ||

Max. Injection pressure | Mpa | 252 | 217 | 189 | 265 | 194 | 149 | 168 | 132 | 107 | ||

Inject stroke | mm | 140 | 140 | 200 | ||||||||

Screw rotating speed | r.p.m | 0~240 | 0~240 | 0~240 | ||||||||

Nozzle protrusion plate size | mm | ≥60 | ≥60 | ≥60 | ||||||||

Clamping Device | Clamping force | KN | 861 | 1125 | 1504 | |||||||

Clamping stroke | mm | 250 | 300 | 300 | ||||||||

Min. Mould thickness | mm | 250 | 250 | 260 | ||||||||

Max. Daylight | mm | 650 | 650 | 610 | ||||||||

Space between bars | mm | 390*660 | 470*660 | 610*650 | ||||||||

Max. Mould size | mm | 450*550 | 550*600 | 550*750 | ||||||||

Ejector stroke | mm | 145 | 175 | 245 | ||||||||

Ejector force | KN | 33.2 | 46.4 | 53.8 | ||||||||

Others | System pressure | Mpa/cm2 | 14 | 14 | 14 | |||||||

Oil tank capacity | L | 365 | 450 | 433 | ||||||||

Heating power | KW | 12 | 12 | 18 | ||||||||

Motor power | KW | 11 | 11 | 18.5 | ||||||||

Size | L*W | mm | 2200*2100 | 2700*2200 | 3900*1150 | |||||||

| H | mm | 2800/3590 | 3300/4200 | 3200/4100 | ||||||||

Gross weight | T | 5.5 | 6.5 | 8 | ||||||||

Customer Show:

Hot sales:

Send to us