Rubber Vulcanizing Press Machine /Rubber Compression Molding Machine/Hydraulic Press Machine

Basic Info

| Model NO. | XH-407 |

| Control Mode | PLC Control |

| Transport Package | Wooden Case |

| Specification | 1000mm*600mm*1500mm |

| Trademark | XH |

| Origin | China |

| HS Code | 8477800000 |

| Production Capacity | 50sets/Month |

Product Description

Product Application:

Mainly used in rubber, plastics, polyolefin, PVC, film, coil, profile, pigments, masterbatch, stabilizer and so on. Its main purpose is to test the raw materials' physical properties change after press. Such as: color dispersion, light transmittance, glossiness of the surface of the material, presence or absence of black spots, the strength, plasticity, hardness change after adding auxiliary materials.Suitable for factory acceptance of the physical properties of suppliers' raw materials, comparison of similar products, and the use of research and development departments of colleges and universities to develop new products. It can be used as a reference for materials before mass production in the factory.

Typical application:

1. Detection of gel (fisheye), black spots, stains, etc. of raw materials2. Raw material compression, color matching, mixing, sample preparation3. Materials physical property test4. Thermoforming of the common rubber, plastic and their composites;

5. Heated pressurized sulfide processing of the common rubber;6. Preparation of simple rubber vulcanization products;7. Vulcanization research of the common rubber;8. Rubber formula design;9. Optimization and control of rubber vulcanization technology;

Features:

1. The press machine have small size but complete in functions, stable temperature and low noise. Easy to operate, save materials and accurate temperature. Suitable for laboratory research and development of new products.2. The controller has the function of proportional bandwidth adjustment and automatic reset. 3. Equipped with a temperature digital display to display the temperature of each plate.4. The large-diameter hydraulic cylinder of solid steel structure contacts the movable worktable, which evenly distributes the load and reduces the plate deviation.5. High-performance hydraulic system, with automatic pressure compensation function, can preset the time and pressure of the first pressurization and the second pressurization. Automatic pressurization and pressure relief, supplemented by high-precision oil cylinders, with a capacity of 10-100 tons6. High-precision, high-wear-resistant guide column, strong load force, stable lifting, and extremely wear-resistant7. Using imported KDB electric heating plate material, high temperature resistance, corrosion resistance, fast heat transfer, not easy to deform8. High-precision temperature sensor, with LED temperature controller and built-in dense spot heating wire, tubular condenser, temperature range 5ºC to 400ºC

Technical Parameter:

| XH-406B-30-300 | Applicable materials | rubber and plastics | |

Capacity | 30 Ton | ||

Temperature range | room temperature - 300°C | ||

Temperature control accuracy | ±2°C | ||

Press plate dimension | 300mm*300mm | ||

Cooling method | running water cooling | ||

No. of working layer | 2 Layers (one for heating, another for cooling) | ||

Control mode | PLC control | ||

Power supply | 380V/50Hz/3 phases or Customized | ||

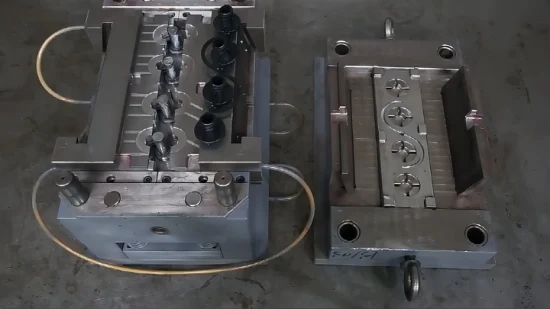

Machine Pictures:

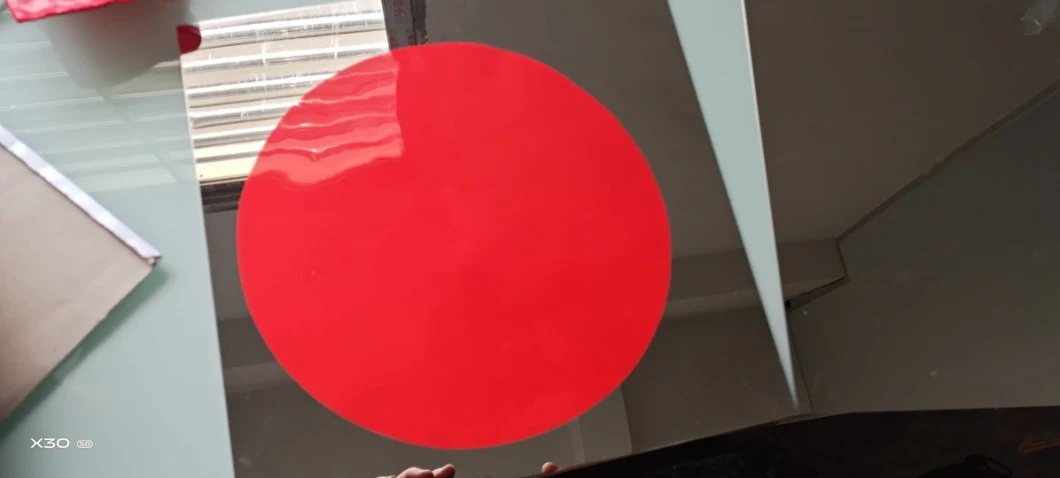

Samples:

Our Workshop:

Our client's laboratory:

Our Team: