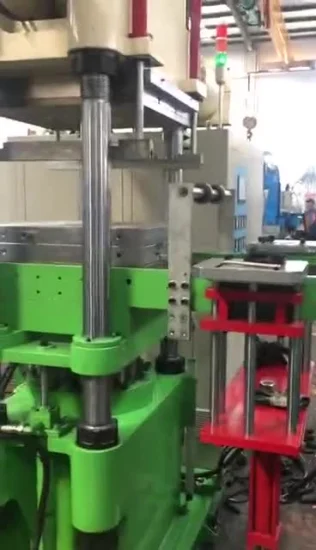

Rubber Injection Molding Press Machine

Basic Info

| Model NO. | JC-RH300T |

| Structure | Vertical |

| Video Outgoing-Inspection | Provided |

| Machinery Test Report | Provided |

| Core Components | PLC, Engine, Bearing, Motor, Gear |

| Voltage | 220V/380V/415V/440V |

| Dimension(L*W*H) | 2900X2355 X4400mm |

| Weight | 8500 Kg |

| Key Selling Points | Famous Brand PLC |

| After Warranty Service | Video Technical Support, Online Support |

| Applicable Industries | Manufacturing Plant |

| Rubber Vulcanizing | Continuous Production |

| Power(W) | 18.5kw |

| Transport Package | Wooden Case and Plastic Film Packed in Container |

| Specification | New Product 2021 |

| Trademark | Evertech |

| Origin | Qingdao, China |

| HS Code | 84778000 |

| Production Capacity | 5 Set/Sets Per Month |

Product Description

Rubber Injection Molding Machine/Rubber Injection Machine/Rubber Injection Press/Rubber Injection Vulcanizing Machine

APPLICATIONS: Ideal for the production of natural &synthetic rubber,oil & heat resistant rubber, and reclaimed rubber.

- Low bed structure

- Equipped with standard PLC controller

- Patented anti-spill device

- Patented material feeding device

- Custom specifications are available

Rubber Injection Molding Machine is ideal equipment for the production of natural &synthetic rubber,oil & heat resistant rubber, and reclaimed rubber.

Highlights of our rubber injection molding machine:

1.Mold handling (ejectors) system: 2RT/3RT/4RT;

2.Pressure & Speed control: proportional pressure and proportional flow control from PLC ensure the operation more stable, can control each movement reliably without causing shock.

3.Safety :all machine movements must immedatiatey stop if operator hand blocks the light curtain. Safety interlock for movements,fool-proof design.Replacement time of lubrication oil can be set up from touch screen and auto alarm.Two button simultaneous pressing must be required to start the operation (Optional).

4. Parallelism of heating platens:0.05mm PER 300mm,precision curing&moulding finishing.

5.PLC programmable controller + touch screen HMI, technical parameters setting is convenient and easy,recipes are storable.The whole process is monitored;internal fault is diagnosed and alarmed automatically.

6.Precise positioning when moving in or out the mold.

7.Mold temperature control accuracy is ±1ºC.

SpecificationDetailed Images