Rotary Type Vertical LSR Silicone Rubber Injection Machine (CE/ISO9001)

1-Name : LSR injection machineLSR injection moulding machineLSR injection molding machineLSR injecting machineLiquid sil

Basic Info

| Model NO. | CX120R2-2C |

| Structure | Vertical |

| Transport Package | Safety Wooden Box |

| Specification | 80T |

| Trademark | CX |

| Origin | China |

| HS Code | 8477800000 |

| Production Capacity | 200 Sets Per Month |

Product Description

1-Name : LSR injection machineLSR injection moulding machineLSR injection molding machineLSR injecting machineLiquid silicone rubber injection machineLiquid silicone rubber injection moulding machineLiquid silicone rubber injection molding machineLiquid silicone rubber injecting machine2-Vertical type,high precision , Excellent performance,double color products.3- Model No.: CX120R2-2C

4-Use:Our products are widely used for automobile manufacturing,medical equipment industry,electronics industry,baby products,daily necessities, optical lenses and so on.5- Main parameters:

| CX120R2-2C | CX170R2-2C | CX250R3-2C | ||||||||||||||

| Series No. | I II A.B SP,A,B | I II B.C SRB,C | I II C,D SP.C.D | |||||||||||||

| Clamping force | 1764(120) KN | 1666(170) KN | 2450(250) KN | |||||||||||||

| (60*2) mm | (85*2)mm | (125*2) | ||||||||||||||

| Open stroke | 280 mm | 300 mm | 400 mm | |||||||||||||

| Mini.mold height | 250(350) | 280(380) | 300(400) | |||||||||||||

| Max.die size | 390*390 | 460*460 | 470*470 | |||||||||||||

| Template size | 0>980 | 01170 | 01360 | |||||||||||||

| Ejector stroke | 50 | 90 | 150 | |||||||||||||

| Ejector force | 17.2(1.75) | 26.5(2.7) | 45(4.6) | |||||||||||||

| System pressure | 13.7(140) | 13.7(140) | 13.7(140) | |||||||||||||

| Motor power | 11(15)+11(15) | 15(20)+15(20) | 22(30)+22(30) | |||||||||||||

| Workbench height | 1360 | 1380 | 1690 | |||||||||||||

| Machine size | 2270*2065*2770(3550) | 2411*2270*3035(3825) | 3525*2455*3584(4544) | |||||||||||||

| Machine weight | 7.0 | 9.1 | 17.4 | |||||||||||||

| Model- Unit | SP | A | B | C | D | |||||||||||

| Screw diameter Φ | 18 | 20 | 22 | 22 | 25 | 28 | 28 | 32 | 36 | 32 | 36 | 40 | 40 | 44 | 48 | |

| Screw stroke-mm | 90 | 110 | 130 | 150 | 175 | |||||||||||

| Injection volume-cm3 | 22.99 | 28.3 | 34.2 | 41.8 | 54 | 67.7 | 80 | 104.5 | 132.3 | 120.6 | 152.7 | 188.5 | 219.8 | 266 | 317 | |

| Max.inject pressure Mpa (kgf/cm2) | 2592 | 2100 | 1735 | 2530 | 1960 | 1563 | 2500 | 1914 | 1512 | 2331 | 1842 | 1492 | 2218 | 1833 | 1540 | |

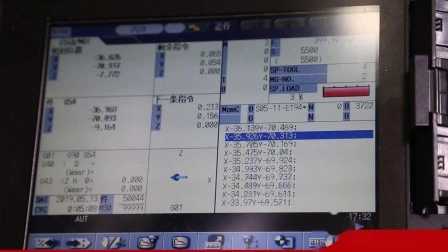

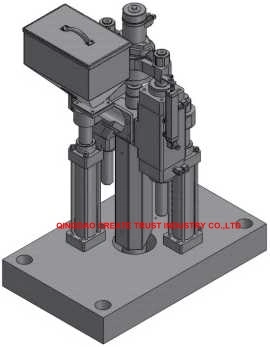

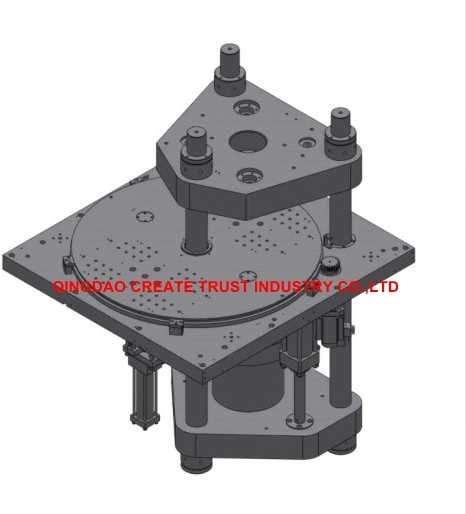

-Injection unit:The injection adopts a two-cylinder balanced injection system to ensure stable and powerful injection.Precise injection volume development range 20- 1000cm3.Repeated injection molding precision control within 0.01mm.Specialized screw length to diameter ratio design, suitable for all kinds of special engineering plastics.The professionally developed high-speed high- pressure injection molding machine is the best choice for injection molding of thin-walled parts.-Clamping unit:The mold clamping adopts the direct pressure type clamping cylinder design.It can quickly lower the clamping and slow low pressure clamping,effectively protect and delay the life of the mold.Simple result, zero maintenance.Full hydraulic clamping unit.The clamping area uses safety gates and electric eye gratings for all-round safety protection and monitoring.-Temperature control range:Barrel, flange, and nozzle all independent temperature control.Feeding port emergency cooling function.Fuel tank hydraulic oil temperature control.-Hydraulic system:Inovance's servo motor is matched with Sumitomo Pump.The oil circuit board is made in Taiwan ZhongqinHydraulic solenoid valve adopts Japan Oil Research Solenoid Valve.The hydraulic system has a simple structure.Self-priming oil plunger cylinder is more energy-saving. High toughness and high strength castings never burst. The special latent sealing hydraulic system has no black oil It has a longer service life.-System controller:The machine controller adopts Austrian KEBA controller. The KEBA controller adopts closed-loop control for all motion and temperature monitoring.The action sequence can arbitrarily set real-time online alarm reminders,error prompts,It adopt ergonomic operation buttons and diversify interface input. Software module expansion is easy to understand real-time curve state tracking, cycle state analysis and optimize various processes, Friendly operation interface, easier to operate Ethernet interface. Easy remote online detection and centralized factory management.-Imported PartsThe bearings of the transmission parts are made of NSK bearings from Japan Hydraulic sealing ring adopts Japanese NOK oil sealThe turntable is driven by Japanese Panasonic servo motorThe reducer is made by Taiwan Li Ming-Other Parts:The bearings of the transmission parts are made of NSK bearings Hydraulic sealing ring adopts Japanese NOK oil sealThe turntable is driven by Japanese Panasonic servo motor.-Multicolor auxiliary shooting platform:It can realize two-color injection molding with one mobile shooting platform. And can be restored to a single at any time. Color injection molding machine, multi-color auxiliary shooting platform mainly has a variety of structures such as top shooting stage, side shooting stage, micro injection molding stage and turntable type.

MACHINES IN EXHIBITION:

Products photos:

7-Service of us :

The production of all products are follow ISO9001:2008 organization system, from raw material processing to assembe and finally test running. even the packing, and delivery. Also we track the use of machine,installation, products producing technical ect.All we do is for longterm cooperation , " CREATE TURST" !

Send to us