High Efficiency Energy-Saving Silicone Rubber Injection Molding Machine

Basic Info

| Computerized | Computerized |

| Certification | CE, ISO9001:2008, GMP, QS |

| Clamping Force | 600~55000 Ton |

| Clamping System | Direct Press |

| Max Tie Bar Distance | 2620*2260 mm |

| Shot Volume | 102018cm2 |

| Transport Package | Wooden Box or Customized |

| Specification | 8*1.5*2.3m |

| Trademark | Elite/customized |

| Origin | Mainland China |

| HS Code | 8477101000 |

| Production Capacity | 3000 Units Per Year |

Product Description

High Efficiency Energy-Saving Silicone Rubber Injection Molding Machine

EVH series all-electric injection machine(600-55000T):Mainly used for medical, 3C electronic, buckets , food package ... industries. Direct press clamping unit,high pressure is directly streesed on the platen center,can extende the plate & mold working life.High presicion plate parallelism,especially suits for deep &multicavity production .Plate positioning precision+/-0.05 mm,suits for high precision production .Longer opening stroke than toggle machines .Hydraulic oilself-lubricate design,nolubrucating oil pollution .

About Us

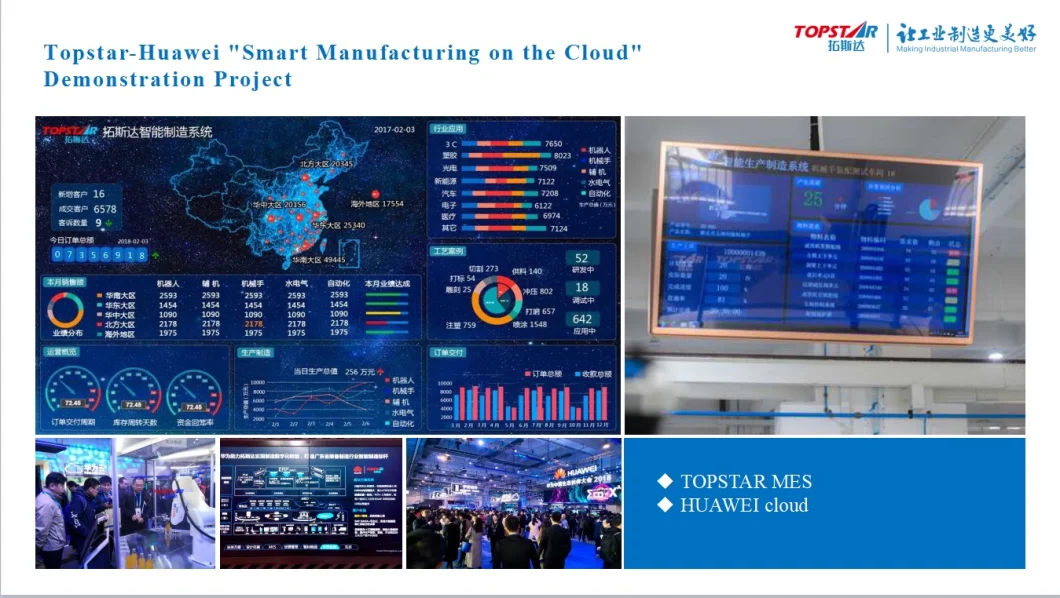

Guangdong Topstar Technology(Abbr. TOPSTAR, stock code: 300607)is the first robot key enterprise listed on GEM in Guangdong province, focusing on the R&D, manufacturing and sale of the industrial robots as the representative of intelligent equipment, dedicated to system integration, product manufacturing, software development and industry internet -- four in one intelligent manufacturing integrated service provider.

TOPSTAR adheres to the brand advocate " Making industrial manufacturing better" and the core value "one year investment return for the automation solution". The core products include intelligent equipment represented by industrial robots, industrial internet of things software represented by control systems and MES, providing customers with turnkey solutions for intelligent production environment based on industrial robots and creating a healthy intelligent manufacturing ecosystem.

There are more than 30 sales and service branches all around the country, and serving for 5000 customers, including Midea, BYD Auto, CHANGCHENG Auto, BIEL, etc.

Our certification and honor

Case show

Thanks for your attention, any question or much more details, please feel free to contact me!